Incoloy Material Stockist

Montex Tubes Industries takes pride in offering a wide array of butt-weld fittings, essential components in piping systems. These fittings facilitate secure and robust connections, ensuring seamless flow and structural integrity within diverse industrial applications. This comprehensive guide delves into the details of our butt-weld fittings, their types, applications, and the quality standards maintained at Montex Tubes Industries.

Types of Incoloy: Incoloy alloys encompass a variety of compositions such as Incoloy 800, 825, each tailored to offer specific advantages in extreme temperature applications.

Materials and Composition: Primarily composed of nickel, iron, and chromium, with the addition of small proportions of other elements, Incoloy alloys exhibit exceptional resistance to corrosion and thermal stability.

Properties:

High-Temperature Strength: Renowned for its exceptional strength and stability in high-temperature applications, making it suitable for extreme heat environments.

Oxidation Resistance: Exhibits remarkable resistance to oxidation, ensuring long-term durability in high-heat and oxidizing environments.

Corrosion Resistance: Offers resistance to various corrosive elements, maintaining structural integrity in aggressive chemical environments.

Creep and Fatigue Resistance: Resists creep and fatigue deformation, ensuring performance and reliability in prolonged high-temperature operations.

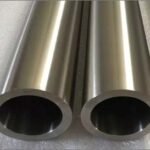

Shapes and Sizes: Available in forms such as pipes, tubes, sheets, bars, and fittings, catering to different dimensional requirements across multiple high-temperature applications.

Technical Specifications: Specifications may vary according to the specific Incoloy grade and type, providing unique mechanical and physical properties.

Applications and Industries: Incoloy alloys find extensive use in aerospace, chemical processing, heat treating, and nuclear applications, signifying their reliability and performance in extreme heat environments.

Standards Compliance: Incoloy adheres to industry standards such as ASTM, ASME, and NACE, ensuring high quality and performance.

Our Commitment at Montex Tubes Industries: At Montex Tubes Industries, we are committed to delivering high-grade Incoloy solutions that comply with rigorous industry standards, ensuring reliability and performance in extreme temperature applications.

Incoloy Composition

Incoloy Melting Point

Incoloy Mechanical Properties

Typical room temperature Tensile Properties of Annealed Material

| Product | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) |

|---|---|---|---|

| Rod & Bar | 75-100 | 30-60 | 60-30 |

What are the Characteristics of Incoloy?

- Good corrosion resistance in aqueous environments

- Excellent strength resistance in high-temperature settings

- Excellent oxidation and carburization resistance in high-temperature settings

- Good creep-rupture strength

- Ease of fabrication

Incoloy Equivalent

ASTM Specifications

| Alloy | Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting |

|---|---|---|---|---|---|---|---|---|

| Alloy 800 (UNS N08800) | B407 | B154 | B163 | B515 | B409 | B408 | B564 | B366 |

| Alloy 800H (UNS N08810) | B407 | B154 | B163 | B515 | B409 | B408 | B564 | B366 |

| Alloy 800HT (UNS N08811) | B407 | B154 | B163 | B515 | B409 | B408 | B564 | B366 |