Hastelloy Material Stockist

Hastelloy, a family of high-performance alloys, exemplifies exceptional corrosion resistance and superior performance, setting a standard in critical industrial applications. At Montex Tubes Industries, we uphold the importance of Hastelloy for its unwavering quality and reliability.

Types of Hastelloy: Hastelloy alloys come in a range of compositions such as C-276, C-22, B-2, and others, each designed to cater to specific environmental and chemical challenges.

Materials and Composition: Hastelloy alloys, comprising various elements including chromium, molybdenum, nickel, and tungsten, offer exceptional corrosion resistance and high strength.

Properties:

Corrosion Resistance: Renowned for its unparalleled resistance to a wide range of corrosive environments, making it ideal for chemical processing, marine, and high-temperature applications.

High Temperature Strength: Withstanding high temperatures and pressures, the alloy retains its mechanical integrity in extreme conditions.

Versatility and Durability: Exhibits superior versatility and durability, offering long-term performance in harsh environments, including acidic and oxidizing settings.

Resistance to Oxidation and Creep: Resists oxidation and creep deformation, maintaining structural integrity in challenging conditions.

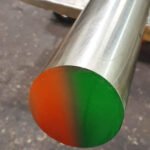

Shapes and Sizes: Available in forms such as pipes, tubes, sheets, bars, and fittings, providing diverse options for various dimensional and application requirements.

Technical Specifications: Specifications may vary depending on the specific Hastelloy grade and type, providing unique mechanical and physical properties.

Applications and Industries: Hastelloy finds application in critical sectors including chemical processing, aerospace, oil and gas, pharmaceuticals, and desalination, signifying its versatility and reliability in demanding environments.

Standards Compliance: Hastelloy adheres to industry standards such as ASTM, ASME, and NACE, ensuring its quality and performance.

Our Commitment at Montex Tubes Industries: At Montex Tubes Industries, we are dedicated to providing top-grade Hastelloy solutions that comply with rigorous industry standards, ensuring reliability and superior performance.

Hastelloy Composition

| Alloy* | C% | Co% | Cr% | Mo% | V% | W% | Ai% | Cu% | Nb % | Ti% | Fe% | Ni% | Other% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy B | 0.1 | 1.25 | 0.6 | 28 | 0.3 | – | – | – | – | – | 5.5 | rest/bal | Mn 0.80; Si 0.70 |

| Hastelloy B2 / Hastelloy B-2 | 0.02 | 1 | 1 | 26.0-30.0 | – | – | – | – | – | – | 2 | rest/bal | Mn 1.0, Si 0.10 |

| Hastelloy C | 0.07 | 1.25 | 16 | 17 | 0.3 | 40 | – | – | – | – | 5.75 | rest/bal | Mn 1.0; Si 0.70 |

| Hastelloy C4 / Hastelloy C-4 | 0.015 | 2 | 14.0-18.0 | 14.0-17.0 | – | – | – | – | – | 0..70 | 3 | rest/bal | Mn 1.0 ; Si 0.08 |

| Hastelloy C276 / Hastelloy C-276 | 0.02 | 2.5 | 14.0-16.5 | 15.0-17.0 | 0.35 | 3.0-4.5 | – | – | – | – | 4.0-7.0 | rest/bal | Mn 1.0; Si 0.05 |

| Hastelloy F | 0.02 | 1.25 | 22 | 6.5 | – | 0.5 | – | – | 2.1 | – | 21 | rest/bal | Mn 1.50; Si 0.50 |

| Hastelloy G | 0.05 | 2.5 | 21.0-23.5 | 5.5-7.5 | – | 1 | – | 1.5-2.5 | 1.7-2.5 | – | 18.0-21.0 | rest/bal | Mn 1.0-2.0; P0.04; Si 1.0; |

| Hastelloy G2 / Hastelloy G-2 | 0.03 | – | 23.0-26.0 | 5.0-7.0 | – | – | – | 0.70-1.20 | – | 0.70-1.50 | rest/bal | 47.0-52.0 | Mn 1.0; Si 1.0 |

| Hastelloy N | 0.06 | 0.25 | 7 | 16.5 | – | 0.2 | – | 0.1 | – | – | 3 | rest/bal | Mn 0.40; Si 0.25; B 0.01 |

| Hastelloy S | 0.02 | 2 | 15.5 | 14.5 | 0.6 | 1 | 0.2 | – | – | – | 3 | rest/bal | Mn 0.50; Si 0.40; B0.0009; La 0.02 |

| Hastelloy W | 0.06 | 1.25 | 5 | 24.5 | – | – | – | – | – | – | 5.5 | rest/bal | Mn 0.050; Si 0.50 |

| Hastelloy X | 0.1 | 1.5 | 22 | 9 | – | 0.6 | – | – | – | 18.5 | – | rest/bal | Mn 0.6; Si 0.60 |

| Hastelloy B-3 | HASTELLOY B-3 alloy is a member of the nickel-molybdenum family of Hastelloy alloys. Hastelloy B-3 is the alloy in the Hastelloy family that shows best resistance to hydrochloric acid. |

| Hastelloy C-276 | HASTELLOY C-276 alloy is a nickel-molybdenum-chromium wrought alloy that is generally used as corrosion-resistance. Hastelloy c-276(Hastelloy C276) is among the more well known Hastelloy grades for general corrosion service. Hastelloy C-276 alloy is an improved wrought version of Hastelloy alloy C. |

| Hastelloy C-4 | HASTELLOY C-4 alloy is a nickel-chromium-molybdenum Hastelloy alloy with good high-temperature stability. The Hastelloy C-4 is an Hastelloy grade, that resists the formation of grain-boundary precipitates in weld heat-affected zones. Hastelloy C-4 alloy also has excellent resistance to stress-corrosion cracking and to oxidizing atmospheres. Hastelloy C-4 is also used in a varity of chemical process environments. |

| Hastelloy G | Hastelloy G is an nickel-chromium-iron-molybdenum alloy developed for corrosion resistance in both oxidizing and reduceing media. Hastelloy G shows good resistance to sulfuric and phosphoric acid. Hastelloy G may further handle both acid and alkaline solutions. |

| Hastelloy X | HASTELLOY X alloy – a nickel-chromium-iron-molybdenum alloy – has been developed to combine oxidation resistance, fabricability and high-temperature strength. Hastelloy X is also It has also been found to be resistant in petrochemical applications. |